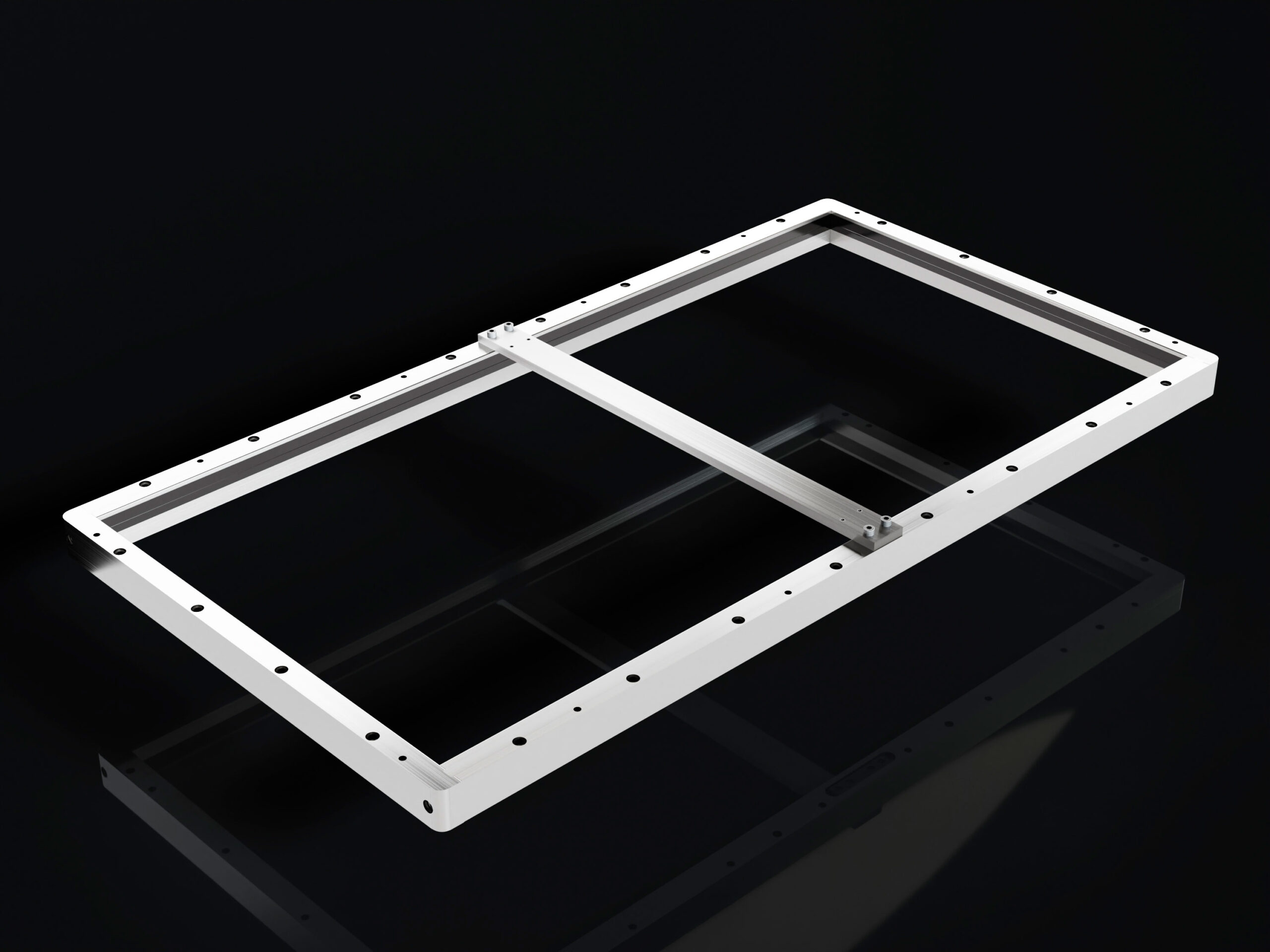

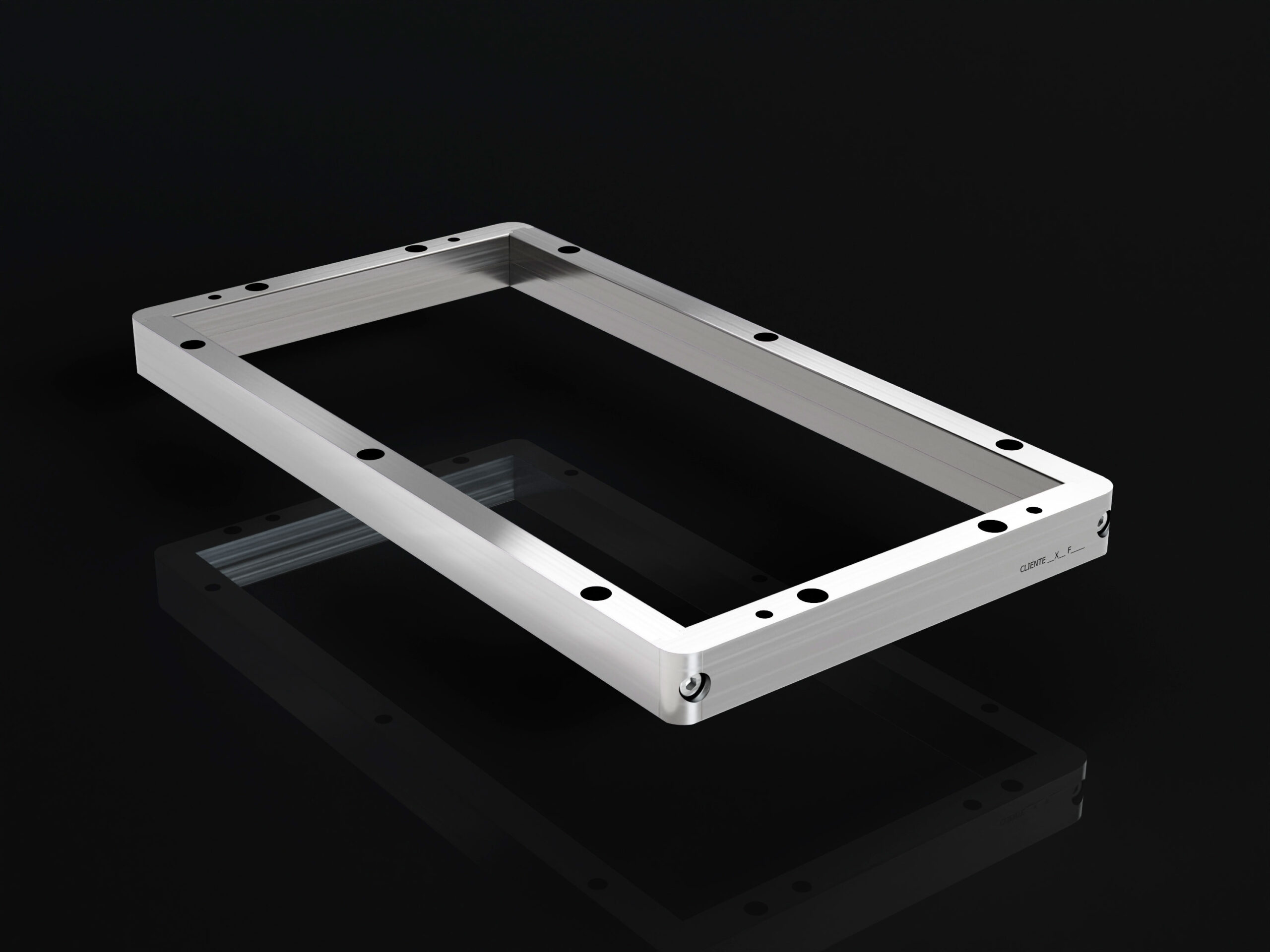

Removable liners, demolding molds

Removable liners

ceramic efficiency and innovation

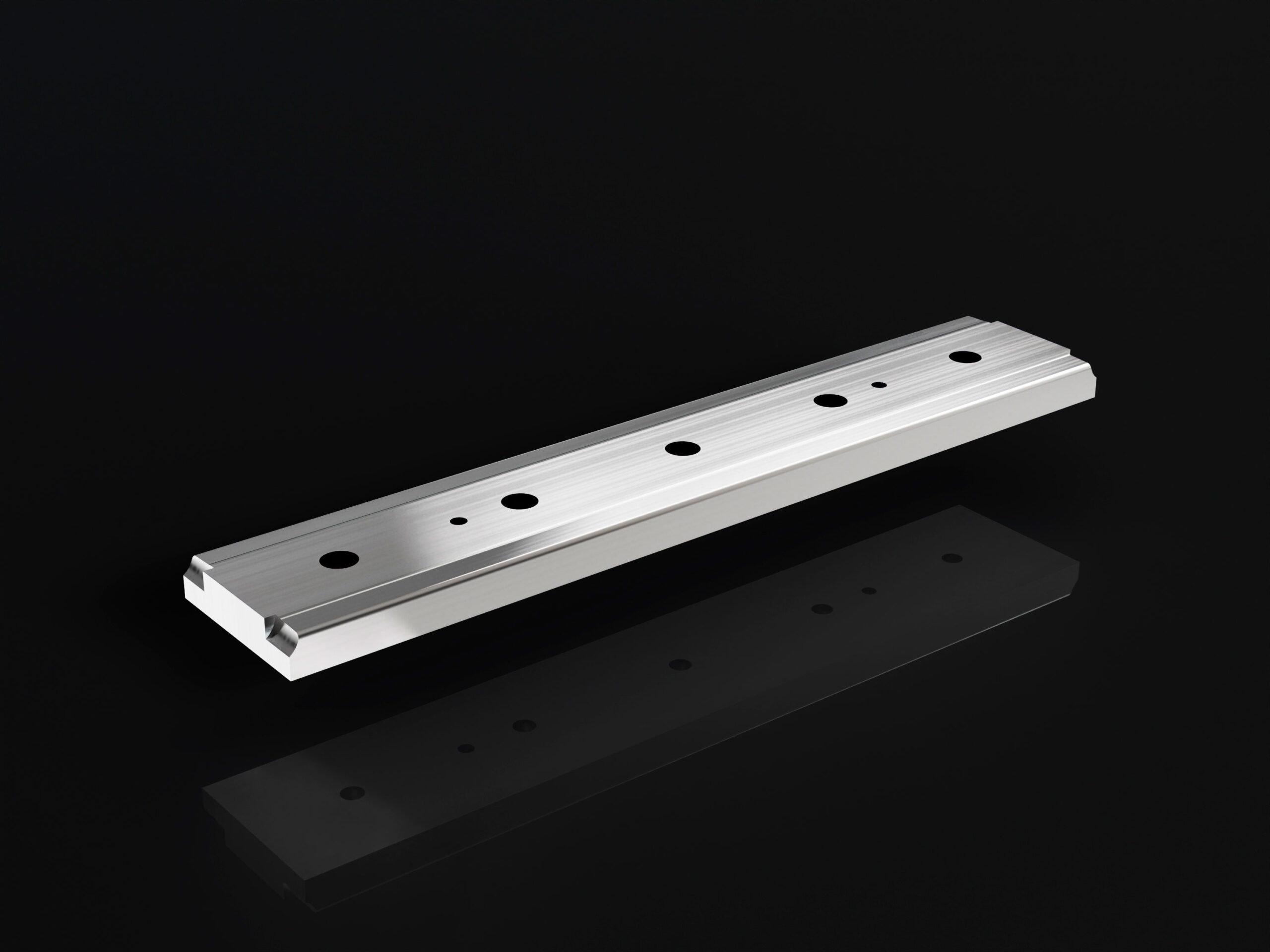

Removable liners, represent a practical and innovative solution in the design of ceramic molds, as they facilitate disassembly and maintenance of each assembly. Their application allows extending the service life of the mold, reducing downtime and optimizing production efficiency. At Cortés, we manufacture removable liners of high precision, adapted to the specific needs of each client and compatible with different mold types. Our goal is to offer tools that simplify daily work, improve versatility and add value to the tile industry.

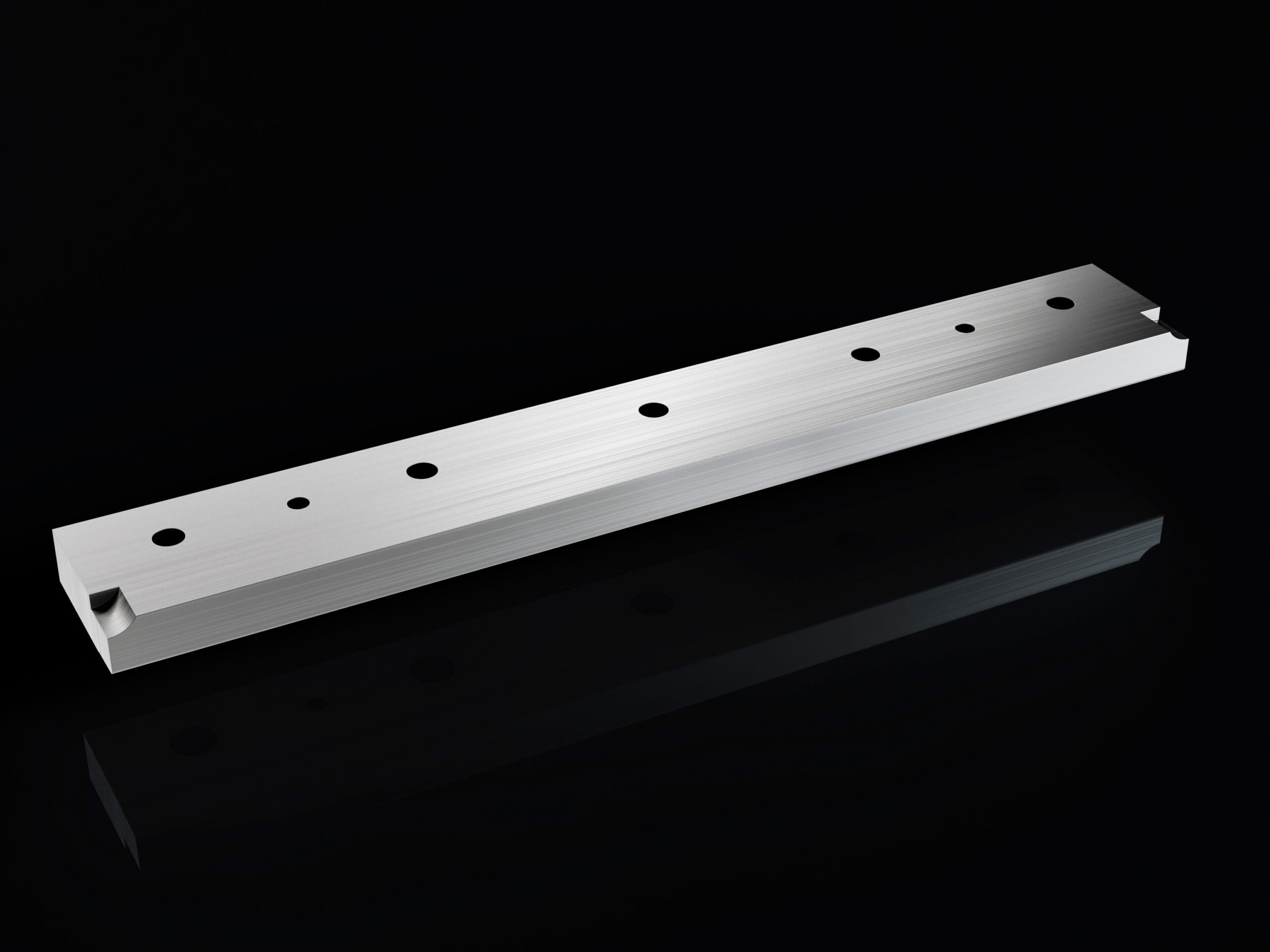

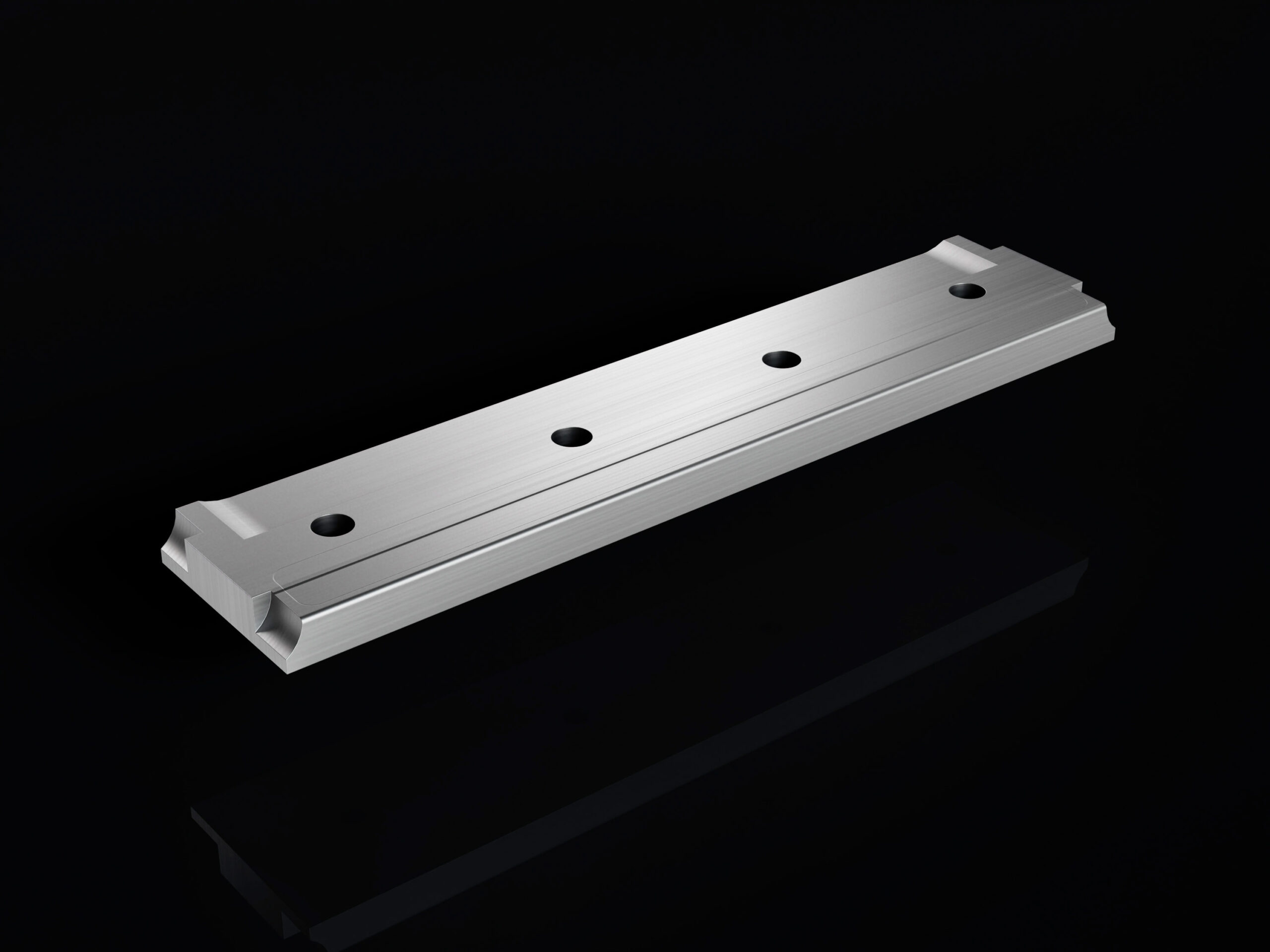

Liners

Interchangeable

Replaceable blades, also called removable, are the second generation or evolution of conventional blades.

In Talleres Cortés, we analyzed the possibility of helping ceramic manufacturers reduce costs, and for this reason, we patented the interchangeable assembled frame, which we usually call "interchangeable blades." The "interchangeable assembled matrix frame" is a patented system with patent number P200102625.

This interchangeable blade system or type facilitates format changes as changing formats is extremely simple and quick, keeping the mold within the press.

Easy to change format

Liners

Tungsten or long-lasting

Tungsten, also known as wolfram or tungsten, is approximately three times stiffer than steel and much denser than steel or titanium. Tungsten carbide has a Mohs hardness rating between 8.5 and 9.0, meaning it is nearly as hard as diamond.

Liners manufactured with this component have a long service life and an extremely high melting point but at the same time a much higher manufacturing cost than standard liners.

It is one of the most resistant, durable, and reliable metals that exist

strength

Discover our solutions

for irregular contours

We use technologies such as EDM, wire cutting, laser, and manual finishing, selecting the most appropriate process in each case according to the needs or requirements of the part. We support each project with our extensive experience in the industry and with the use of state-of-the-art machinery, guaranteeing results of the highest precision and quality.