High precision in ceramic molds

Ceramic molds for tile production

accuracy, durability and process control

In Talleres Cortés we design and manufacture ceramic molds capable of meeting the demands of the tile industry, guaranteeing pressing stability, dimensional accuracy, and minimal downtime requirements. Our experience allows us to develop both standard molds and special solutions adapted to specific geometries and requirements.

Each design is carefully studied to ensure reliable operation, optimal integration with the press, and consistent performance even in demanding working conditions. Discover how our molds can improve the efficiency and results of your pressing processes.

Molds

Penetrant

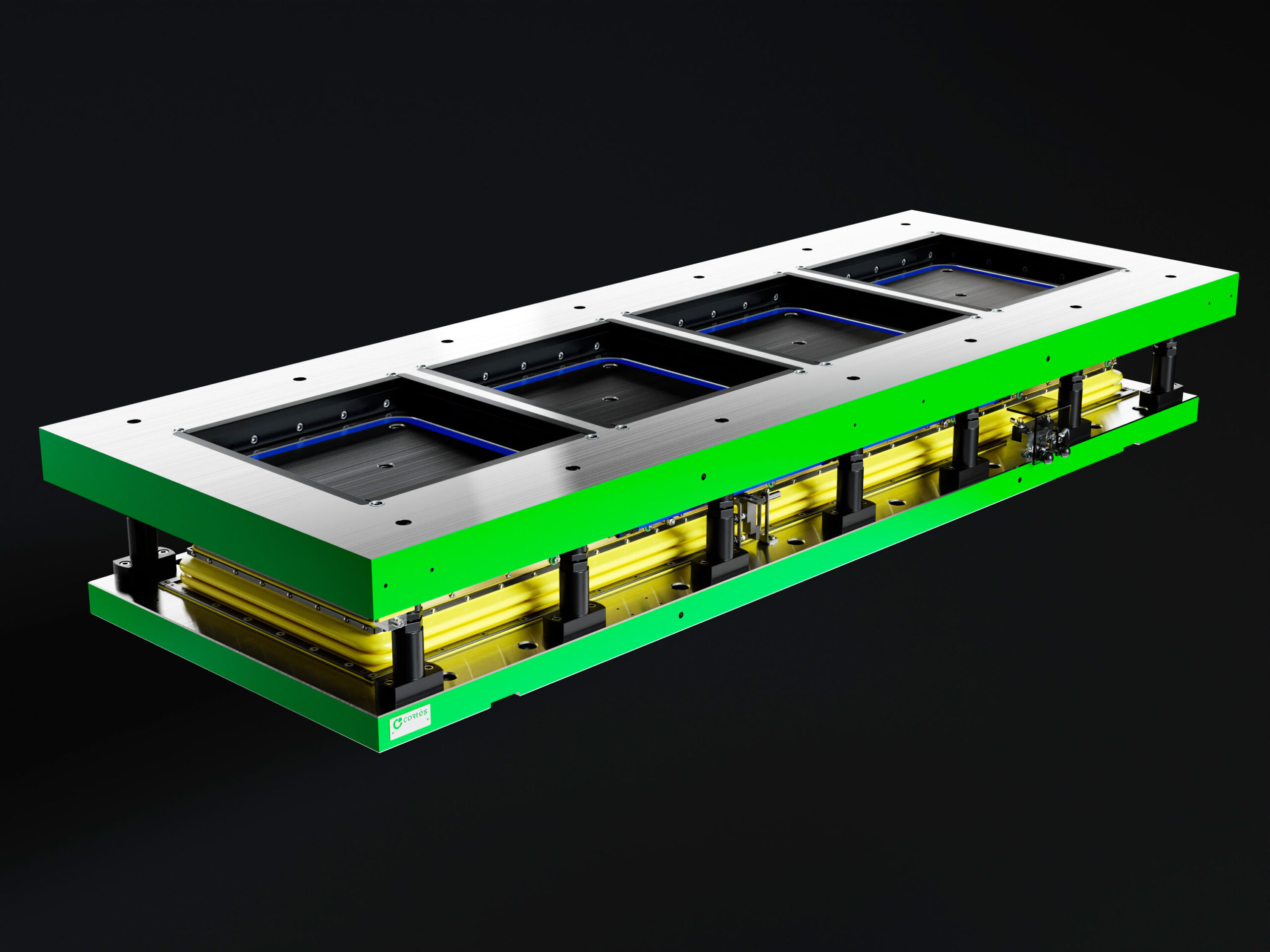

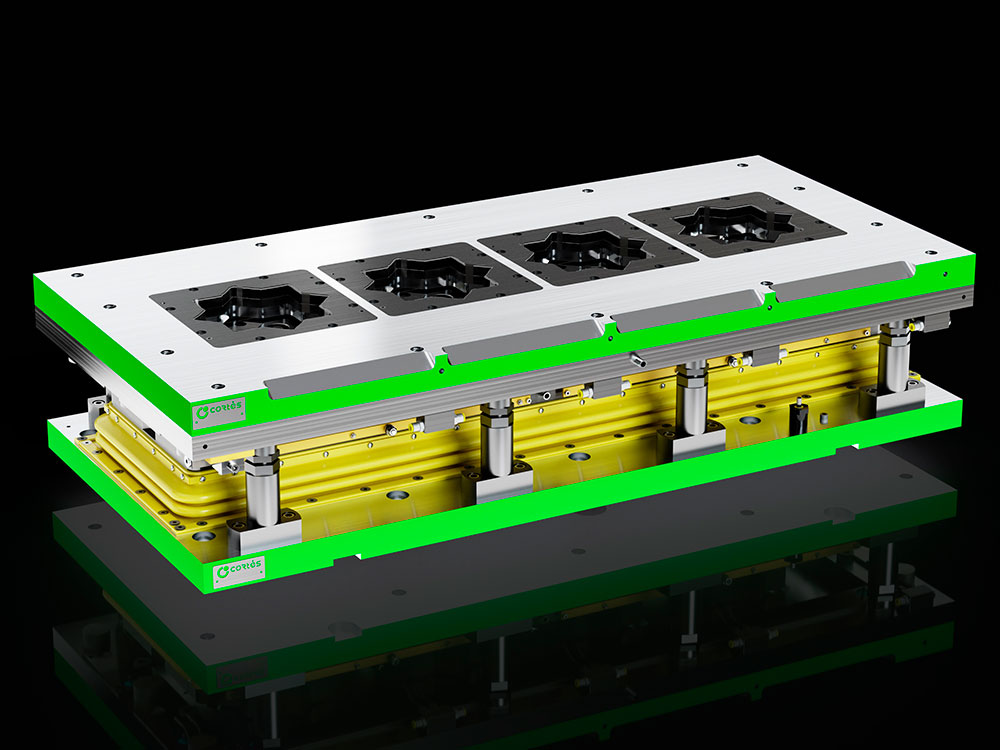

The penetrating mold is the most common. In this mold, the punch coupled to the upper plate is the one that moves, “penetrating” (hence the name) into the cavity/cavities of the die, which remains fixed.

It is normally used for pressing ceramic pieces with the good side facing down.

Allows manufacturing tiles with spacer

These are the molds with the lowest complexity

Molds

Semiespejo / Semipenetrante

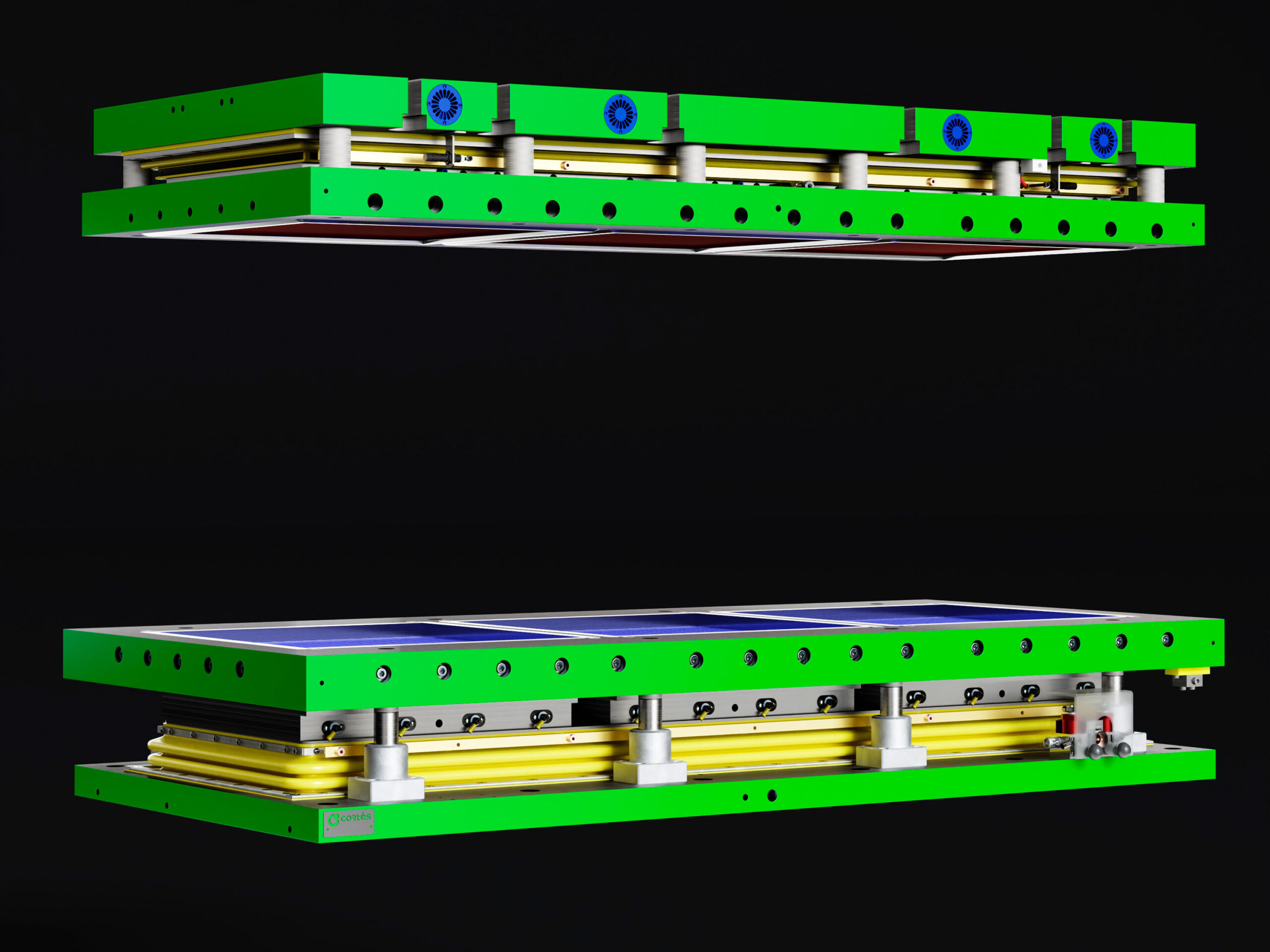

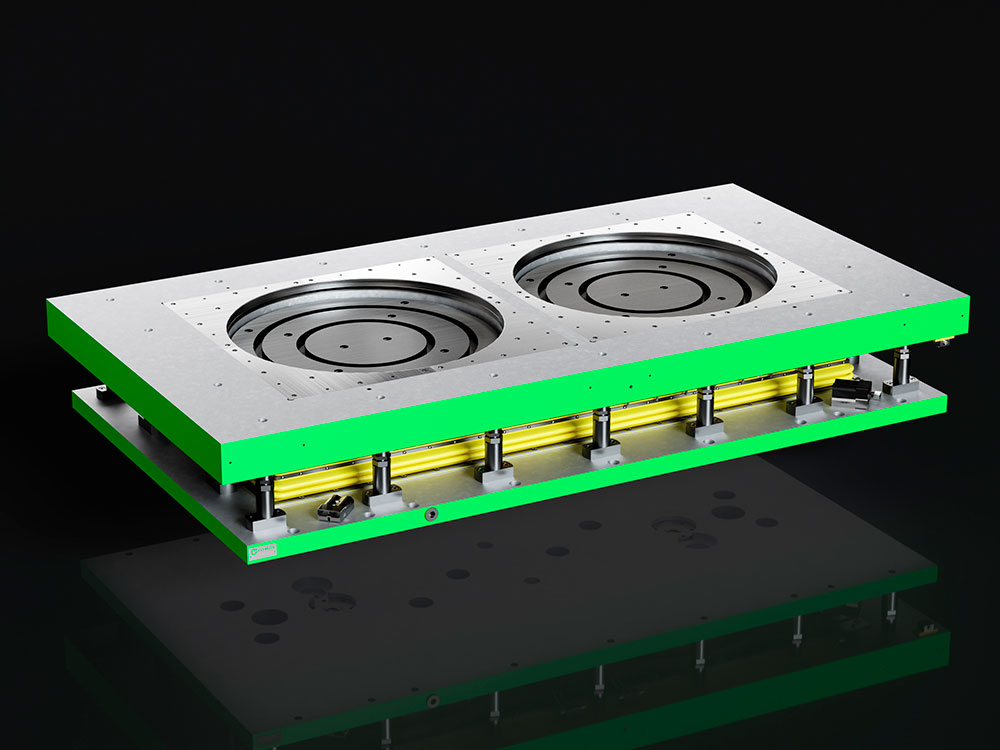

The semi-penetrating or also called semi-mirror mold makes the upper punch enter the cavity of the die to a fixed depth.

Normally, the good face of the ceramic piece is molded on the top side.

The matrix is not fixed as in the case of the penetrant mold

The spacer is not molded in the pressed part

This type of mold is of medium complexity

Molds

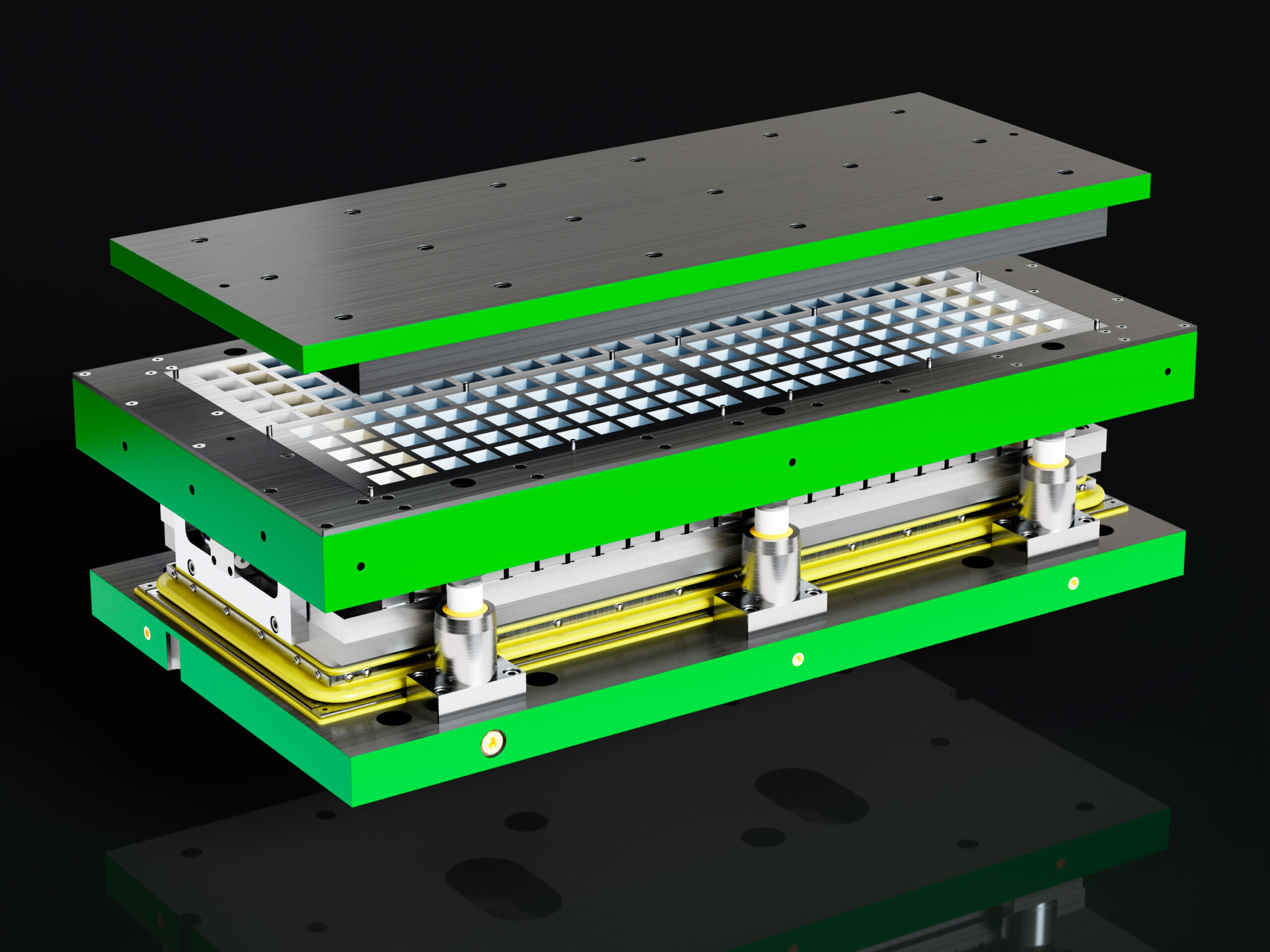

Double mirror

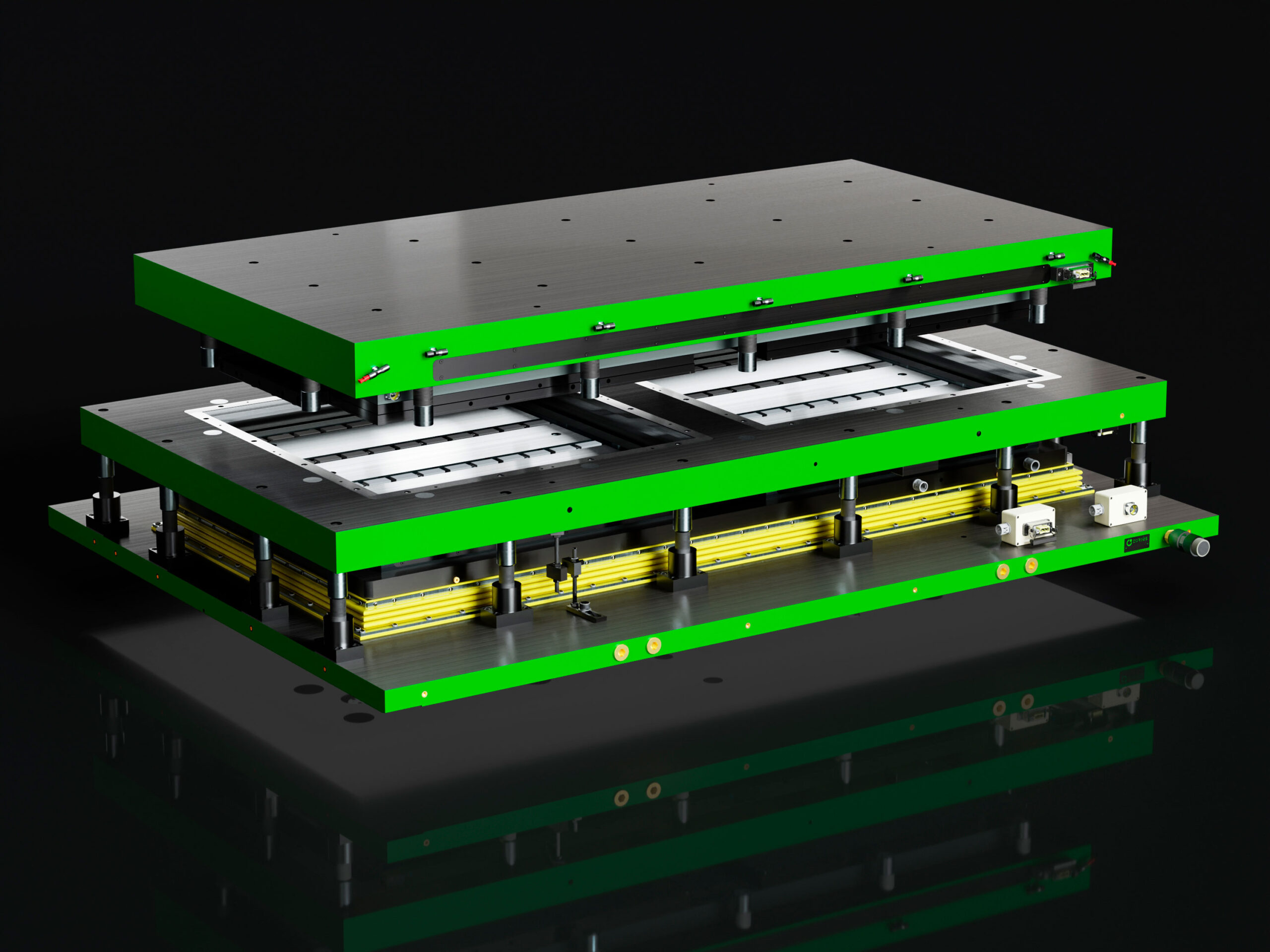

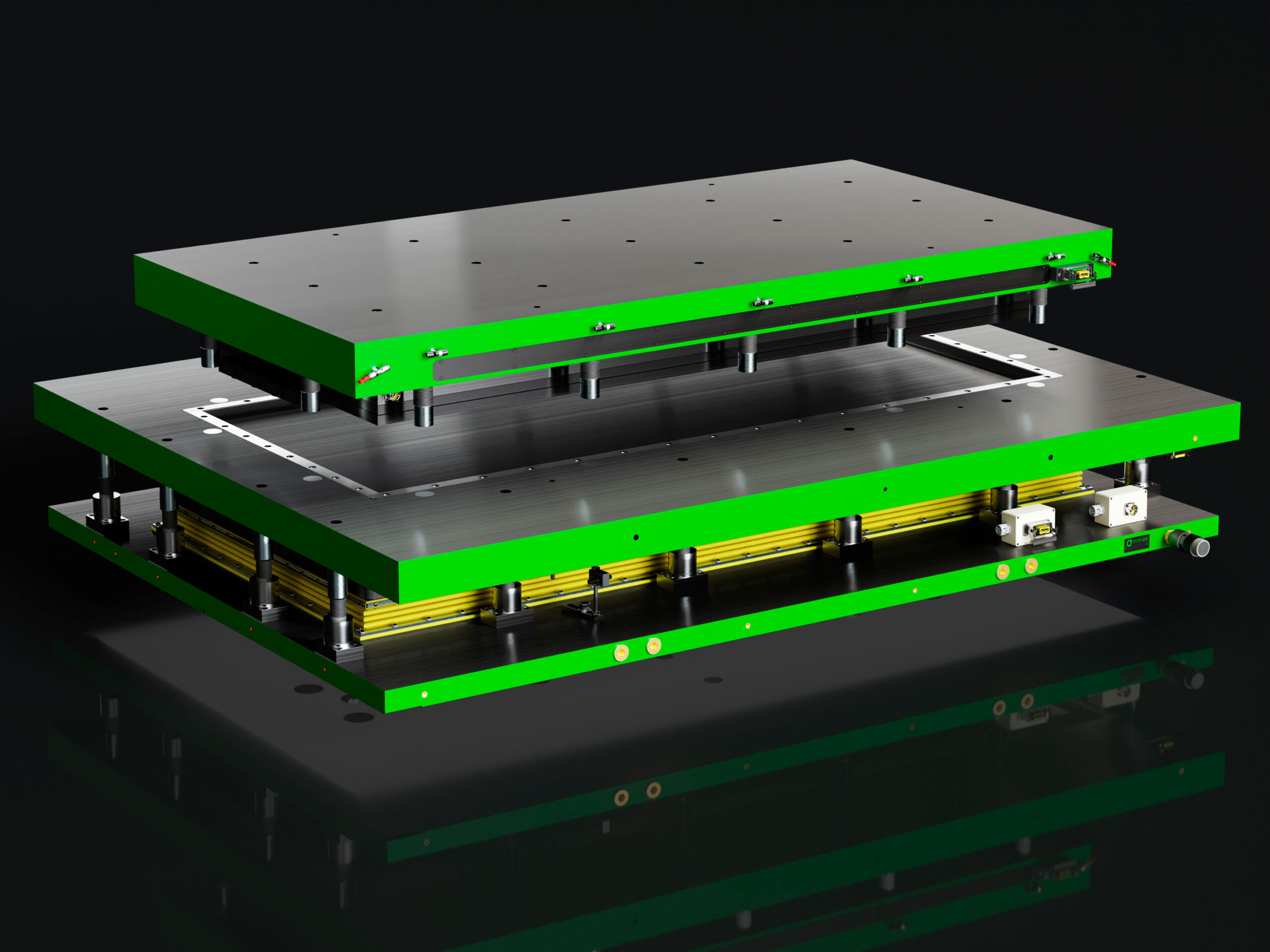

This type of mold is called double because it is composed of two matrices, one on the top and another on the bottom. The double mirror mold forms the tile on the top with the good face of the tile upwards.

The bottom matrix is movable

The tile is molded with spacer

This is a mold with high complexity compared to the rest of the mold types

Longer tool life

Pressed tile higher quality

Homogeneity during the pressing process between the different cavities

Productivity optimization

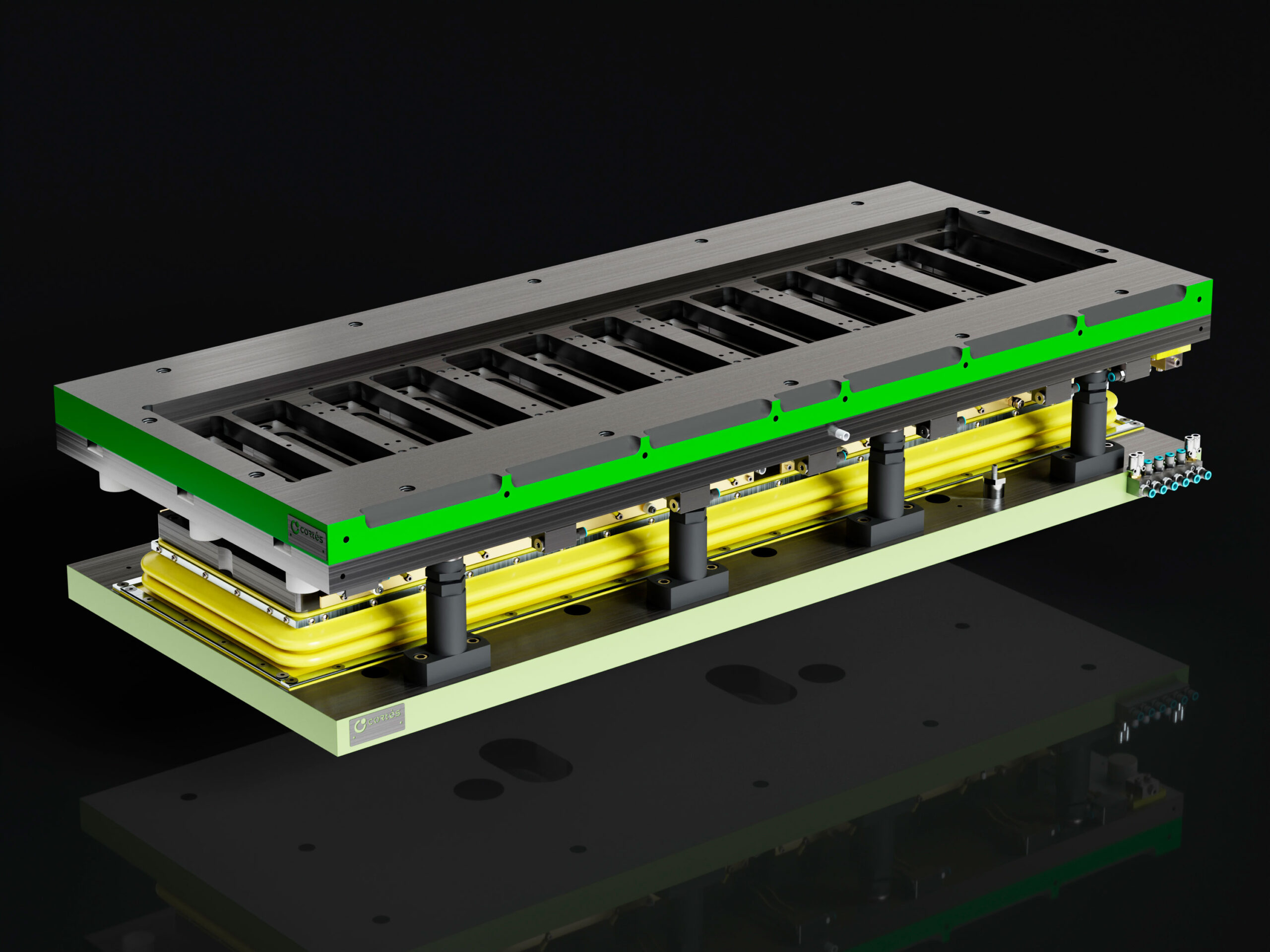

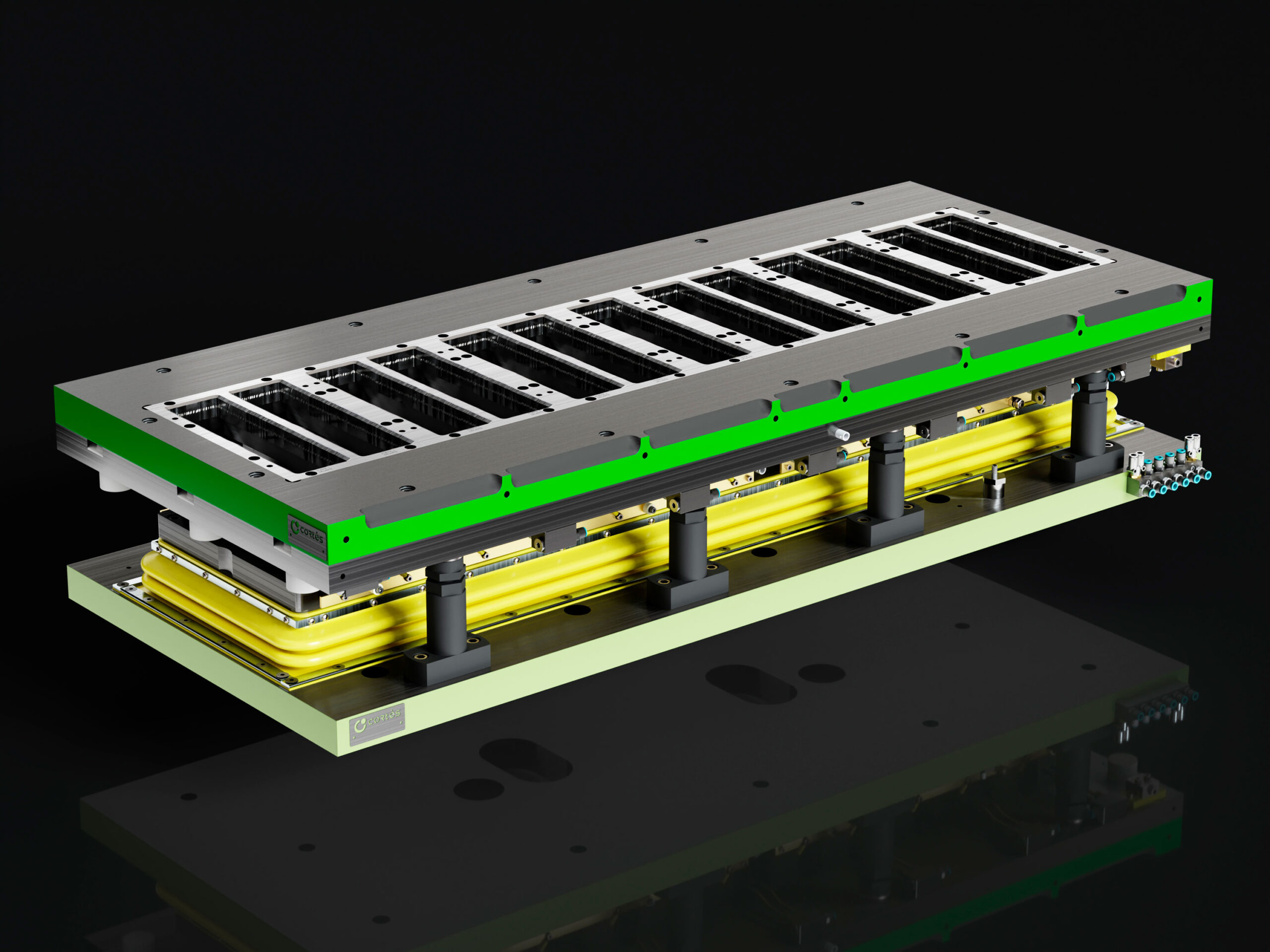

and cost reduction with molds

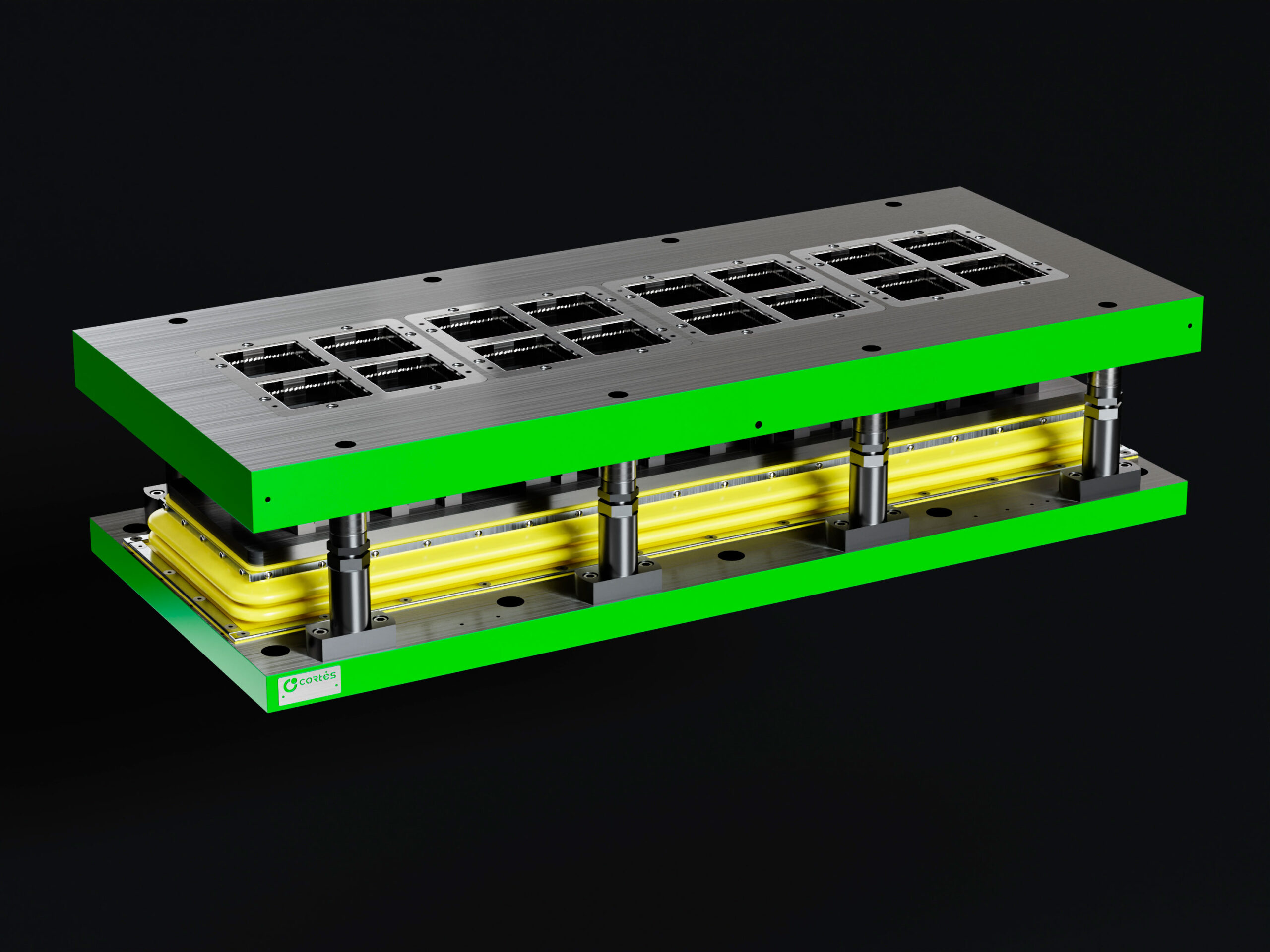

Talleres Cortés manufactures advanced molds designed to optimize productivity and reduce production costs, capable of simultaneous pressing of two rows of parts in each cycle and easily adaptable to different formats or designs through quick replacement of supplements and blades, providing great versatility and efficiency to the manufacturing process.

Custom molds

Multiformat

Molds multi-format: allow manufacturing of two different formats or designs with the same mold, by simply changing supplements and blades, reducing setup times and manufacturing costs.

Manufacturing of two different formats or shapes on the same mold

Easy supplement and blade changes

Custom molds

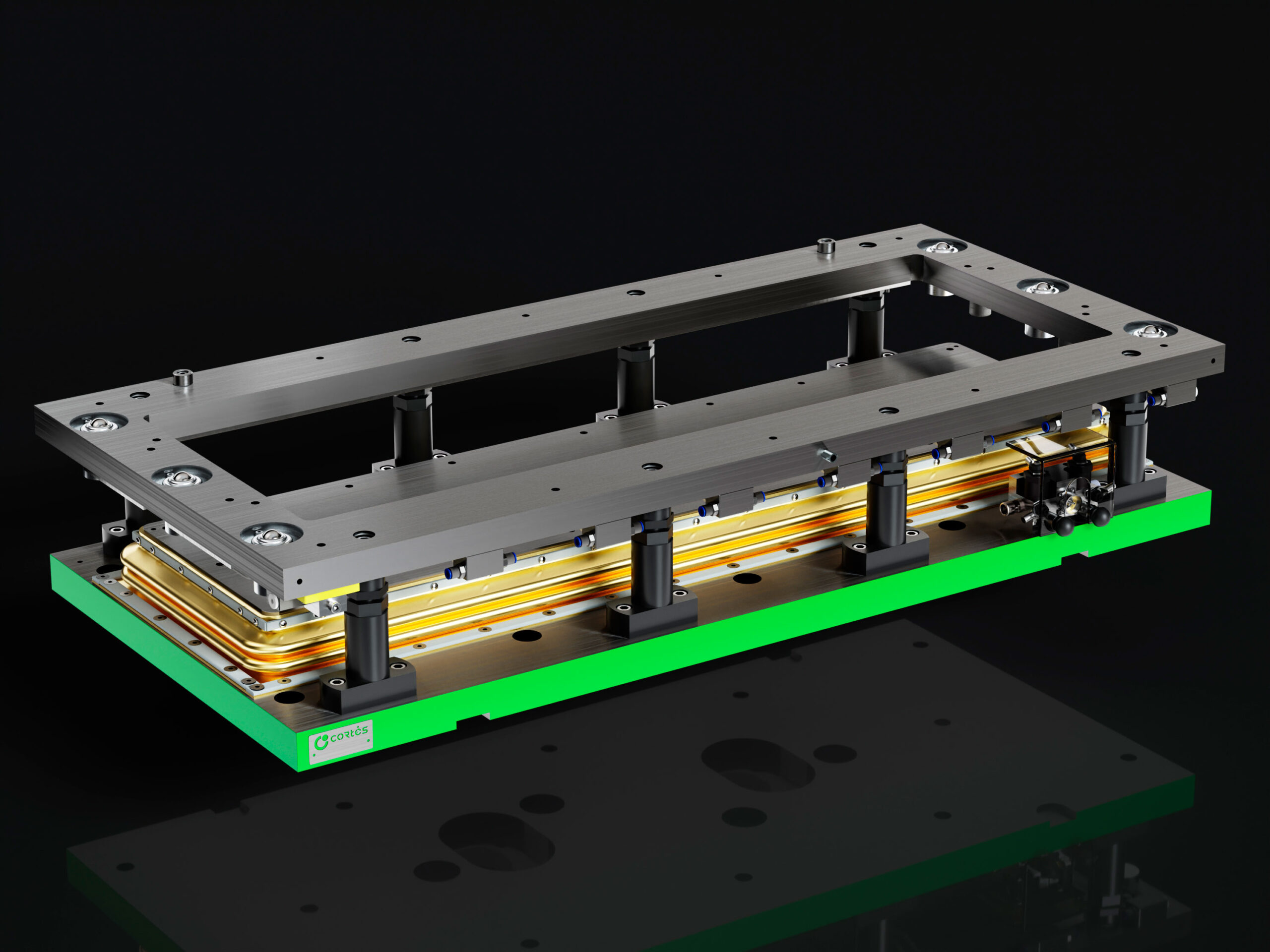

Large formats

CORTES has also specialized in the manufacture of molds for large formats, of 1, 2, 3, outlets and in different configurations. Due to the trend towards manufacturing large-size tiles, it is necessary to use steel punches with considerable weight. To facilitate the extraction of these heavy large-format punches, a hydraulic system with pistons has been incorporated, which lifts the punches, making them protrude from the die. This allows operators to handle them better and to carry out model changes more easily.

Blocks incorporating punch-lifting pistons

Precision